How to remove the rust of 16Mn seamless square pipe during long-term storage?

How

to remove the rust of 16Mn seamless square pipe during long-term storage?

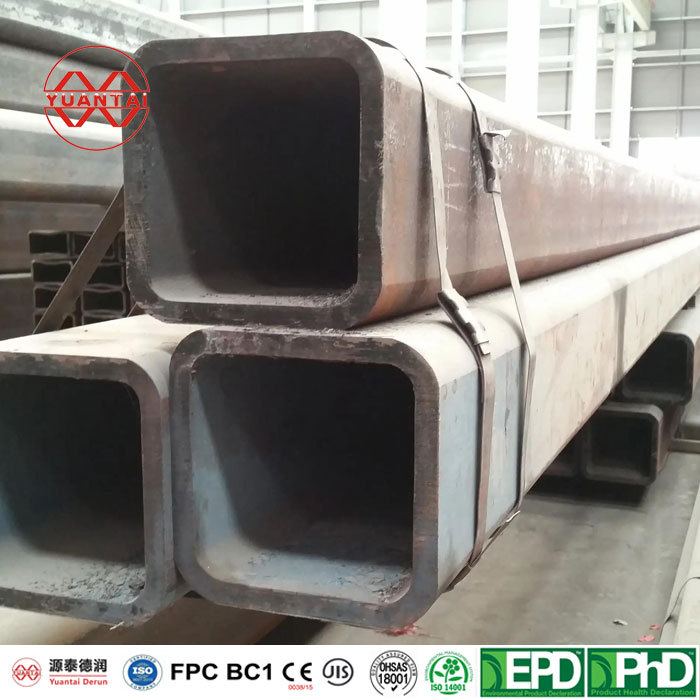

At present, 16Mn seamless square pipe technology has been extremely mature, and there are corresponding product standards and various types of application technologies. Its application fields are also extremely wide. Due to the influence of weather and environment, the surface of 16Mn seamless square pipe will rust after continuous use. How to remove the rust spots of 16Mn seamless square tubes? I will talk about it and analyze it for you.

1. In order to achieve the ideal derusting effect of 16Mn seamless square pipe, it is necessary to determine the abrasive according to the hardness, original corrosion degree, required surface roughness and coating type of alloy pipe, such as single-layer epoxy, two-layer or three-layer polyethylene coating. In order to achieve the ideal derusting effect, it is necessary to use the mixed abrasive of steel sand and steel shot. Since the steel shot can strengthen the steel surface, the steel sand can corrode the steel surface.

2. Derusting grade: compared with the construction process of epoxy, ethylene, phenolic and other anti-corrosion coatings commonly used for 16Mn seamless square pipes, the basic requirement is to make the surface of alloy pipes reach near white level. Practice has proved that the rust removal grade can remove almost all the oxide scale, and the dirt such as rust can fully meet the Attachment requirements of anti-corrosion coating and alloy pipe. The spraying rust removal technology can stably and reliably make the quality reach the near white level, and the cost is low.

3. Before spraying treatment, grease and oxide scale have been removed from the surface of 16Mn seamless square pipe. It also needs to be preheated to 40-60 ℃ by a heating furnace to keep the surface of the alloy pipe dry. Since the surface of the alloy pipe does not contain grease and other dirt, the rust removal effect can be enhanced. In addition, the dry alloy pipe surface is also beneficial to the separation of steel shot, steel sand, rust and oxide scale, which will make the alloy pipe after rust removal.

4. In order to obtain better uniform cleanliness and roughness distribution of 16Mn seamless square pipe, the research and invention of abrasive particle size and proportion are particularly important. Because the roughness is too large, the anti-corrosion coating is easy to become thin at the peak of the anchor line, and because the anchor line is too deep, bubbles are easily formed in the anti-corrosion process, which seriously affects the performance of the anti-corrosion coating.

The essence of aging strengthening treatment is to precipitate many particularly fine precipitated particles from supersaturated solid solution to form the same small solute atom enrichment zone. In order to ensure that not too much solute is dissolved in the solid solution when heating the 16Mn seamless square tube, and then the solubility ratio in the rapid cooling, so that the excessive solute introduced too late will form supersaturated solid solution, quenching needs to be carried out before aging treatment. In the heat treatment process of 16Mn seamless square tube, the heating temperature should be strictly controlled during aging treatment to make the solute dissolve into solid solution as much as possible without melting the alloy.