What Kind Of Test Is A Salt Spray Test?

Salt spray test, as a widely used accelerated corrosion testing method, is an important means of evaluating the corrosion resistance of materials or products in salt spray environments. Understanding salt spray testing can help you better understand the corrosion resistance of materials.

Definition Of Salt Spray Test

Salt spray test, as a widely used accelerated corrosion testing method, is an important means of evaluating the corrosion resistance of materials or products in salt spray environments. It simulates salt spray conditions in marine climate or industrial environments to quickly detect and predict corrosion issues that products may encounter during actual use, providing valuable reference for product design, manufacturing, and use.

The Purpose Of Salt Spray Test

Salt spray testing is widely used in multiple industries, such as automotive, aerospace, electronics, construction, etc., to detect the durability and reliability of materials and products such as metals, coatings, plastics, rubber, etc. in salt spray environments. Through salt spray testing, the service life of materials or products in actual usage environments can be predicted, providing important basis for product design, material selection, and quality control.

How To Do A Salt Spray Test?

During the testing process, the salt spray test chamber will create a closed environment filled with salt spray, and the test sample will be placed in it for a period of time. After the test is completed, the corrosion resistance of the sample is evaluated by observing its corrosion condition, such as corrosion area, corrosion depth, corrosion rate, and other indicators.

Salt Spray Corrosion Test Conditions

The salt spray test is conducted at a temperature of 35 ℃± 2 ℃, using a 5% NACL solution with a settling rate of (1-3) mL/(80cm2. h). The test involves spraying salt spray for 24 hours and drying for 24 hours as one cycle, with a total of 96 hours of testing. In order to provide a higher level of confidence in the equipment's ability to withstand corrosive environments, the number of cycles can be increased, or a 48 hour salt spray and 48 hour drying test procedure can be used.

Salt Spray Test Steps

What is the standard procedure for salt spray test?Now,it has those steps.

1). Adjust the temperature of the test chamber to 35 ℃, and keep the test piece under this condition for at least 2h before spray.

2). Spray salt spray for 24 hours or as specified in relevant documents. During the whole spray period, the salt spray sedimentation rate and the pH value of the settling solution shall be measured at least once every 24 hours to ensure that the salt solution sedimentation rate is (1-3) mL/(80cm '· h).

3). Dry the specimen for 24 hours or as specified in relevant documents under standard atmospheric conditions of temperature (15 ℃~35 ℃) and relative humidity not exceeding 50%. During the drying period, the technical state of the specimen cannot be changed or its mechanical state cannot be adjusted.

4). At the end of the drying stage, unless otherwise specified, the specimen should be reset in the salt spray test chamber and b) and c) should be repeated at least once.

5). Conduct physical and electrical performance testing, record test results (if necessary, take photos). If it is helpful for subsequent corrosion inspection, the specimen can be gently rinsed with flowing water under standard atmospheric conditions before testing and recording the test results.

6). Visually inspect the tested components and record the inspection results.

Salt Spray Test Standard

Salt Spray Test Standard including : IEC 60068-2-52,ASTM C1202,ASTM E96,ASTM 1249,ISO 9227、GB/T 10125、ASTM B117(NSS)、ASTM G85(AASS),etc.

Salt Spray Test Cost

In China, national certified laboratories like Yuantai Derun charge a fee based on time for conducting a salt spray test, which is approximately 4.2-6.5 yuan per hour. Roughly divided into experimental time lengths such as 1000 hours, 2000 hours, and 3000 hours.

Salt Spray Test Result Interpretation

The correct interpretation of test results is crucial for evaluating the corrosion resistance of materials. The following is a comprehensive method for interpreting the results of salt spray testing:

1、 Rating judgment method

Rating determination method is one of the most commonly used methods, which measures the percentage of corrosion area to the total area and evaluates it according to pre-set standards. Different standards (such as ISO10289, GB/T6461, etc.) specify different rating levels and corresponding corrosion area percentages. This method is simple and easy to implement, but subjective and requires strict adherence to standards to reduce errors.

2、 Weighing determination method

The weighing determination method evaluates the degree of corrosion by measuring the weight change of the sample before and after the test. After the experiment, the corrosion products on the sample need to be removed, and then its weight should be accurately weighed. The greater the weight loss, the more severe the corrosion. This method is relatively objective and suitable for precise assessment of metal corrosion resistance quality, but the operation is relatively cumbersome.

3、 Determination method for appearance of corrosive substances

The method for determining the appearance of corrosive substances mainly observes the appearance of corrosive substances on the surface of the sample, such as rust spots, bubbles, peeling, etc. Determine the corrosion resistance of the material based on the degree and type of corrosion. This method is intuitive and easy to implement, but subjective and difficult to quantify the degree of corrosion. Applicable to the evaluation of general product standards.

4、 Corrosion data statistical analysis method

The corrosion data statistical analysis method evaluates the corrosion resistance of materials by statistically analyzing the corrosion data of multiple samples, such as calculating the average corrosion rate, standard deviation, etc. This method can reduce the randomness of individual sample results and improve the reliability of evaluation, but it requires a large amount of experimentation and data processing.

5、 Interpretation precautions

1. Understand the testing standards: Different testing standards (such as neutral salt spray test NSS, acetate salt spray test AASS, etc.) have different testing conditions and evaluation criteria. When interpreting the results, it is necessary to clarify the standards on which they are based.

2. Pay attention to experimental conditions: Experimental temperature, humidity, salt solution concentration, and other conditions have a significant impact on the results, and the influence of these factors should be considered when interpreting.

3. Comprehensive analysis: Combining multiple judgment methods, comprehensively analyze the experimental results to obtain a more accurate evaluation.

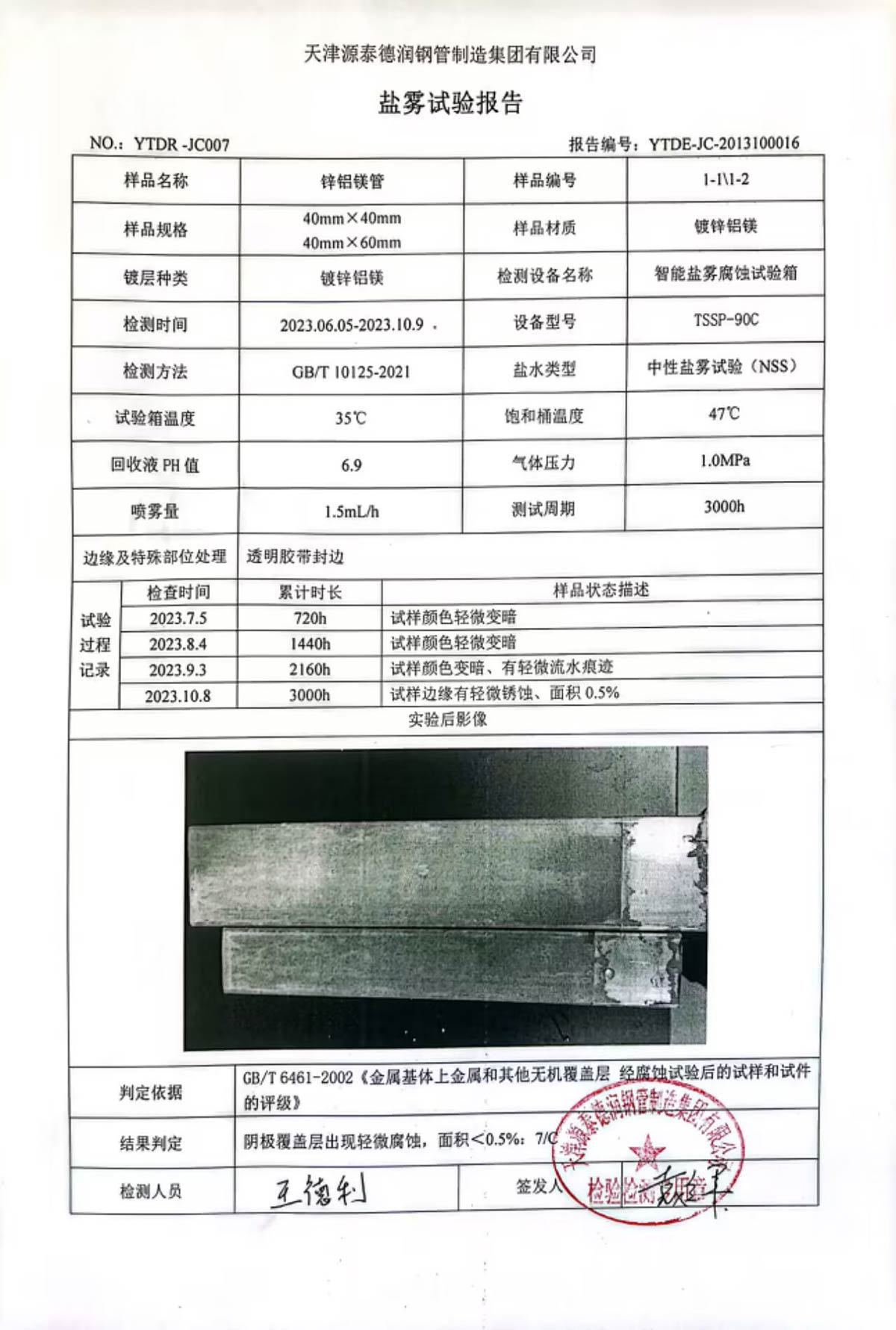

Appendix: 3000 Hour Salt Spray Test Report